-

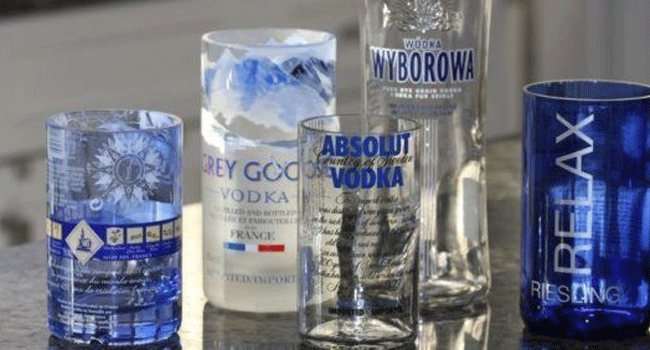

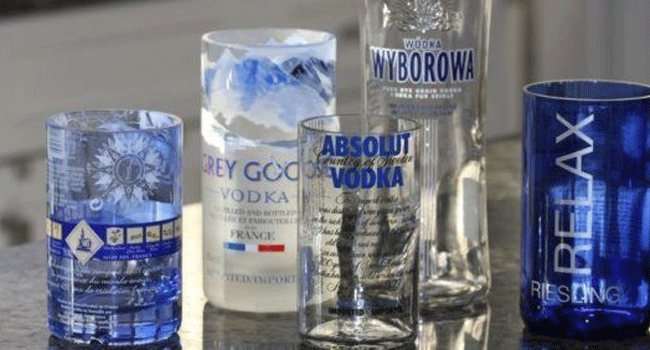

Glass bottle 3D relief UV printing

Transforming glass bottles into art using 3D relief UV printing

-

Transparent container

High Productivity UV-LED Inkjet Printer for Taper / Cylinder Printing

-

Glass bottle

lndustrial Inkjet Printer for 360° Seamless Taper/ Cylinder Printing

-

Tumbler water bottle

High Productivity UV-LED Inkjet Printer for Taper / Cylinder Printing

-

Cup printer

UV Printer -Stainless Steel

-

Candle

lndustrial Inkjet Printer for 360° Seamless Taper/ Cylinder Printing

-

Sports water bottle

Bottle & Growler Printer -UV Printer

-

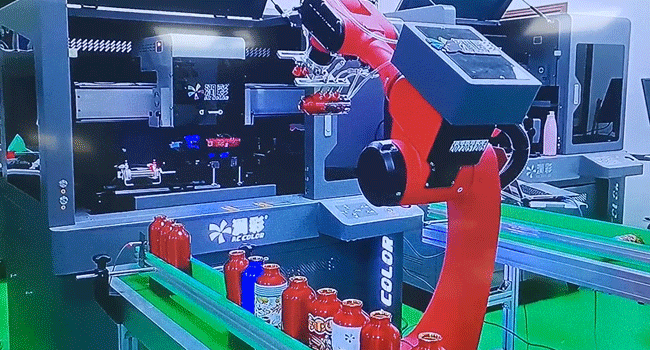

Aluminium can

High Productivity UV-LED Inkjet Printer for Taper / Cylinder Printing

-

Stainless Steel

High Productivity UV-LED Inkjet Printer for Taper / Cylinder Printing

-

Stainless Steel

lndustrial Inkjet Printer for 360° Seamless Taper/ Cylinder Printing

-

Plastic bottle

Bottle & Growler Printer -UV Printer

-

Glass kettle

Bottle & Growler Printer -UV Printer